Suitable for the residual impurities on the surface of the polarizing plate after cutting

Suitable for residual impurities such as coke ballast and carbon black produced after PCB board laser cutting

Residues after laser engraving

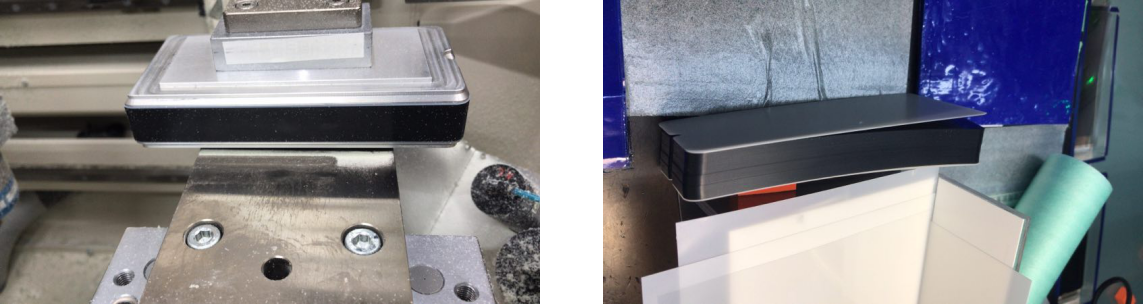

Why clean?

Answer: There are a lot of organic matter and particle impurities on the surface of plastic products, which will affect the electroplating process of the next section of the product. If the cleaning is not thorough, the electroplated product will be unqualified.

Cleaning equipment: BLASTCO cleaning system

Testing equipment: 40 times optical magnifier

Cleaning range: organic matter and particulate impurities on the surface of plastic products

Cleaning difficulties and advantages: general cleaning equipment on the surface of plastic products is easy to wash the product with organic matter and particulate impurities, and the product at right angles is not clear and thorough. The BLASTCO system can easily solve the problem.

Corner area, without any washing product phenomenon

Comparison of results after cleaning: There are more organics and impurities on the surface of the product before cleaning, and there is no organic matter and particle impurities on the surface of the product after cleaning, and there is no scuffing on the surface.

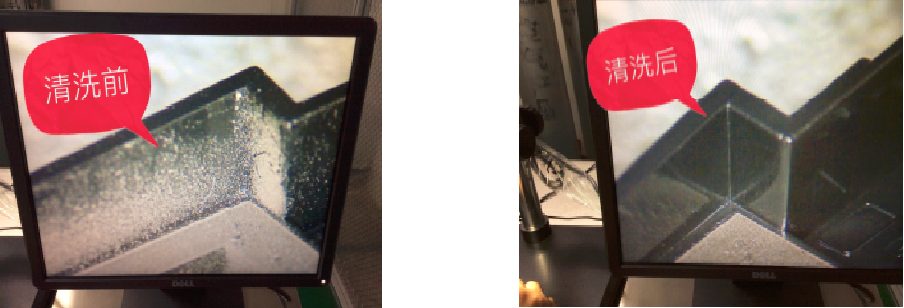

Polarizing plate cleaning series

| Before cleaning: | After cleaning: |

Why clean?

Answer: The display screen has a viewing angle. The viewing angle of the newly installed display is set according to normal use. If it is dirty during installation, its viewing angle will shift and directly affect the viewing of the screen. Sharpness, resulting in low image brightness and unclear picture.

Cleaning equipment: BLASTCO cleaning system

Cleaning range: the residual impurities and organic matter of the polarizer during the cutting process

Cleaning difficulties and advantages: no liquids such as water and mist are generated during the cleaning process, and there is no residue on the surface after cleaning, which does not affect the imaging effect of the polarizer

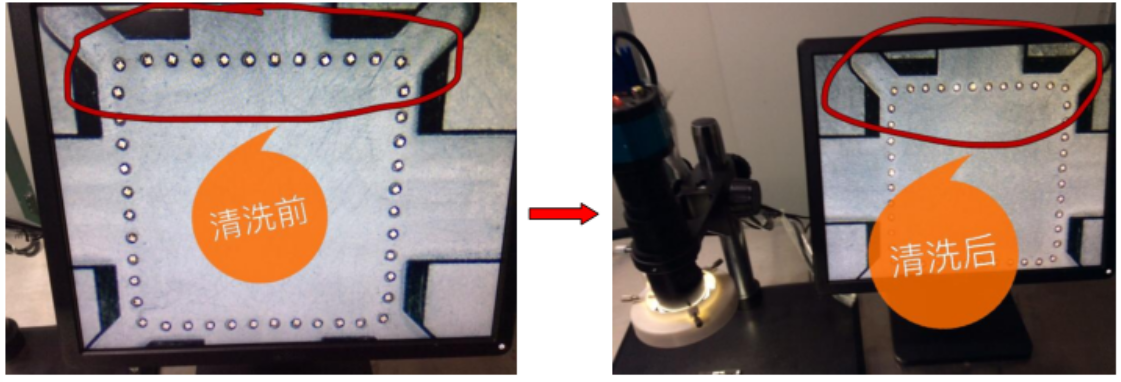

SIP plug-in cleaning

Why clean?

Answer: There are many impurities in the pinholes of the product, and the surface is easy to produce oxides, which will cause the conductivity of the SIP plug-in to deteriorate and affect the performance.

Cleaning equipment: BLASTCO cleaning system

Testing equipment: 40 times optical magnifier

Cleaning range: golden pin inside the SIP plug-in (each golden pin hole is about 1.0mm)

Cleaning advantages: The golden pinhole position is small, and it is difficult to clean by manual or other cleaning methods. The BLASTCO system can easily solve the delicate and small parts.

Comparison of results after cleaning: The golden pin inside the SIP plug-in is dull and has impurities before cleaning. After cleaning, the golden needles are as clean as new without impurities in the holes

URL:www.blastco2.com

mailbox:lisahe@blastco2.com

Address: 2nd Floor, West Side of No. 3 Workshop, 1398 Zizhu Road, Yushan Town, Kunshan City